How wasteful

is your business?

30/10/19

Are you a wasteful business? It's an interesting question to ask of yourself and your business. When working with our clients, we like to ask this question quite early on.

Typically in business, we make decisions based on very limited amounts of data. Understanding how wasteful a business is, or how much profit a business is missing out on, is no different. The less you know, the less effective you will be in dealing with it.

The more you know about the true nature of waste in a business, the faster you can do something about it, and the sooner you can start to capture the profitability that most businesses are missing out on.

We love the 7 wastes approach to waste audit and elimination, because, quite frankly, it works. Waste comes in many forms and most businesses have more waste than they think.

Here are some types and examples:

1. Overproduction

Producing more than is needed to meet a customer's need or to produce it before it is required. It is the result of producing to the ‘Just in Case’ scenario instead of ‘Just in Time’. Over producing, overstaffing, over-catering - you get the idea...

2. Waiting

Somebody is always waiting for something, somewhere. Examples are payment from debtors, stock supply lead time, staff to become available, a management decision - almost endless examples...

3. Transporting

Customers do not want to have to pay for transportation between processes, so this is a clear source of a non-value cost. Also every transport event is an opportunity for damage/loss to occur and the quality to deteriorate. Examples are excessive material handling, too many suppliers, poor warehouse layout, multiple deliveries, incorrect methods of timing and travel.

With this, don't just think of external freight, think of both internal and external movements of people, goods and information workflow. Transport audits always show areas of cost and time recovery.

4. Inappropriate Processing

This can be easily explained by using the analogy ‘using a sledge hammer to crack a nut’. Are you using the right tool/process for the job? Are you using big, expensive, high precision equipment when simpler tools would suffice? Are you using the right person for the job? Again, every sector has a version of this, from senior fee earner getting involved in junior role activities, to expensive equipment being used for a job when a more cost efficient alternative would have been more suitable.

5. Unnecessary Inventory

Work in Progress (WIP) is a direct result of overproduction and waiting. Reducing WIP allows other problems to surface.

The analogy often used is that of a ship sailing along on a sea of WIP which hides rocks below the water level. Lowering the water level of the sea of WIP allows the problems to be addressed as they surface. If this is not done there is a high probability that the ship will run aground.

Examples include finished goods, working capital, medical supplies ( date sensitive )...

6. Unnecessary Motions

This waste is related to ergonomics and time management issues. Examples of this impact are poor factory layouts resulting in wasted time, space, output, office layouts, desk layout ( can drive a "stop/start" mentality )...

7. Defects

These cost money, either now or later and their costs impact directly on the bottom line. They can be internal defects found before sale and incur the costs of scrap, rework or delays.

They can also be external defects which have been delivered to customers and incur the costs of warranty claims, on-site repairs and potential loss of customers, brand and reputational damage.

Think poor instructions, errors through misread orders, manual errors, poor workmanship, poor base materials, poor training, missing deadlines. Any many examples in every sector...

So you've found waste everywhere, and worked out the true commercial cost/benefit and you're keen to crack on with your waste recovery. What next?

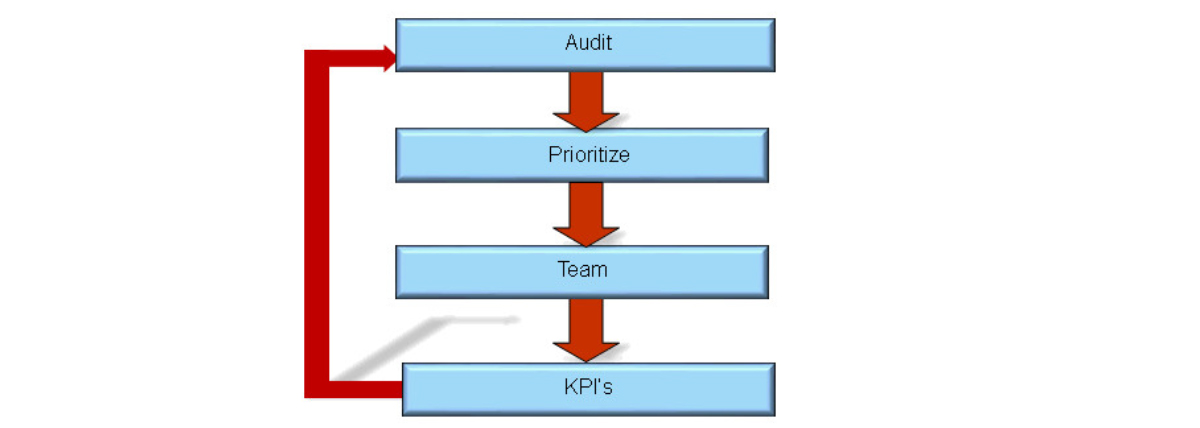

The trick now is having a systematic recovery and elimination plan, no different to any other part of your business strategy. Depending on the type of business you run, this can sometimes be quite an easy process to integrate.

One of our recent clients, who by their own admission were relatively unaware of the level of waste in their business, used the process to isolate thousands of £s worth of waste to recover, using 7 wastes as part of a waste audit and recovery toolkit.

So if you're one of those business owners who wonders what impact a waste recovery audit would have on their business/growth/profit, consider 7 wastes as a starting point.

If you're interested in setting up a waste recovery plan for your business and need to know where to start, get in touch and we’ll work with you to get going with your own time and profitability recovery journey.

For those of you who feel like getting started yourself, good luck and let us all know how you get on. Be great to see who recovers the most!